Welcome to South Downs Woodturners

|

|

|

|

South Downs Woodturners meet on the last Wednesday of each month at the Beeding and Bramber Village Hall.

Beeding & Bramber Village Hall, High Street, Upper Beeding, West Sussex, BN44 3WN

Meetings start at 7.00pm.

There are refreshments available but please bring your own mug!

See our Contact page for a Map and our About / Prog page for activities.

If you would like to join us please come to any meeting without obligation and meet our Membership Secretary. For further info please e-mail us at Enquiries@SouthDownsWoodturners.com

|

Next Meeting Click here for details of the next meeting

May 2024 - Bowl

See our Competition Page for details and previous results

Chairman's Challenge

|

April 2024

Barry Chidlow took the floor for this month's demonstration, showing how to make a child's chair based on some plans from Roy Jones.

Don't forget about our Facebook group, which is a great way to keep in touch with members and to show what you have been doing! Find the group here.

March 2024

Gordon Eaton returned with another engaging and absorbing demo showing how to go from a log to a bowl. He covered timber preparation, storing, rough turning, coring and then finish turning in his own inimitable style, complete with a few jokes. The demo was very well received. Thank you, Gordon!

Don't forget about our Facebook group, which is a great way to keep in touch with members and to show what you have been doing! Find the group here.

March 2024

Turnings and Tools table - bring an item each month for the table for display...and be in with a chance of winning a club pen!

February 2024

Kevin Hutson was a welcome return demonstrator for the February meeting, covering how to turn a square box with winged corners.

Don't forget about our Facebook group, which is a great way to keep in touch with members and to show what you have been doing! Find the group here.

January 2024

Norman got the year started with a demonstration covering aspects of pen-turning, including safe ways of drilling the pen blanks.

December 2023

Mince pies and turned snowmen dominated the final meeting of the year. See you all again in 2024. Happy New Year!

November 2023

In a change of programme, as our booked demonstrator was unable to demo, we had a hands on evening with several lathes out and the sharpening corner set up. We also collected in more snowmen that are being donated to a nursery for children to decorate. It was a very enjoyable evening as the photos show!

Check out all the year's demos on our About/Prog page.

October 2023

In a change of programme, Gordon Eaton stepped in for Norman Billingham, and showed how to inlay a ring of resin in a bowl rim. He covered the subject in detail, explaining the necessary steps to create a recess for the resin and the best way to shape this. He showed how to mix, colour and pour the resin, and then after the tea break and raffle, he showed how to turn the rim to reveal the resin on the back of the bowl as well as the front. He then showed how a couple of ways of how to finish the resin. An informative and enjoyable evening that also included our competition - congratulations to the winners. Don't forget to bring turned snowmen to the next meeting - about 5 inches tall, sanded, ready for painting.

Check out all the year's demos on our About/Prog page.

September 2023

Patrick O'Connell demonstrated for us - starting with a turned pen that uses a Bic refill, followed by an off-centre candlestick. After the break, Pat then turned his hand to captive rings, which are often found on goblets. He has found that people don't buy the goblets, but a turned stem with captive rings on sells well for him, so that is what he made with tools he had made from drill bits. It was an entertaining and enjoyable evening.

Check out all the year's demos on our About/Prog page.

August 2023

August's meeting was a hands on evening with several lathes out for various demonstrations, a sharpening clinic and the show and tell table. It was a well attended and enjoyable evening - as the photos show!

Check out all the year's demos on our About/Prog page.

July 2023

Wednesday 26th July 2023, 7pm, Beeding and Bramber Village Hall, BN44 3WN

It's competition time - so don't forget your embellished piece of woodturning for the competition table. This month's demo will be from club member Barry Chidlow who will be showing how to make a fun illusion. Remember to bring in items for the Tools 'n' Turnings table as well as your competition piece!

Check out all the year's demos on our About/Prog page.

June 2023

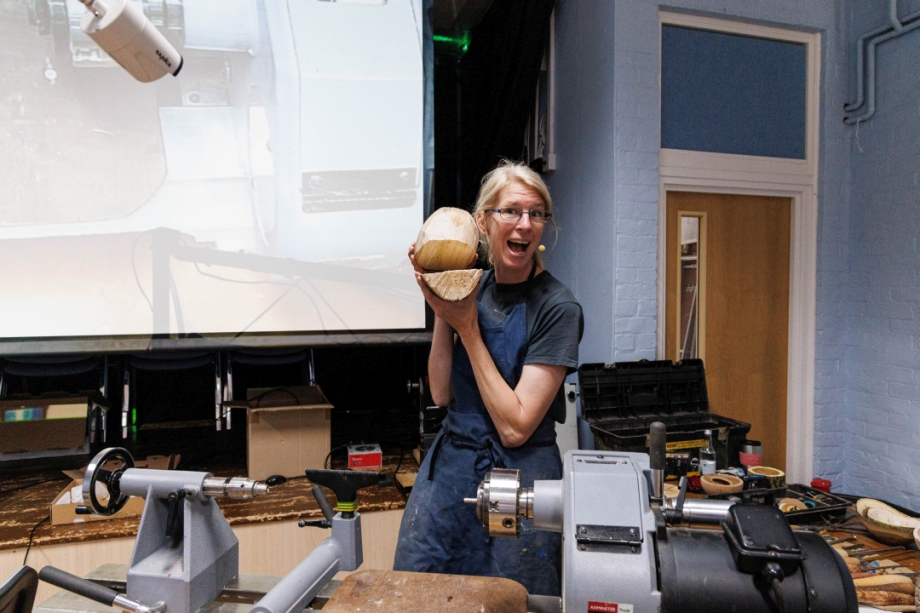

Anna gave an absorbing and engaging demo on turning green wood, focusing on natural edged bowls. She covered design ideas, workholding, and cutting techniques. As well as showing cross grained turning, there was also time for a quick look at the ring tool on an endgrain bowl. There was lots of participation and discussion from the audience. A really enjoyable evening!

Check out all the year's demos on our About/Prog page.

May 2023

Wednesday 31st May 2023, 7pm, Beeding and Bramber Village Hall, BN44 3WN

Members were treated to an interactive remote demonstration from professional turner Chris Parker aka "The Bald Woodturner." Chris demonstrated a variety of texturing and colouring techniques. This was great inspiration for our July competition - "Embellishment of Turned Pieces" Website: https://www.thebaldwoodturners.co.uk/

Check out all the year's demos on our About/Prog page.

April 2023

Our Chairman,Norman Billingham, demonstrated some turning incorporating rare earth magnets. This took place after the club's AGM. It was also a competition night, so check out the results on our Competition Page.

Check out all the year's demos on our About/Prog page.

March 2023

In March we welcomed back Terry Smart from Chestnut Products, who demonstrated a range of his products. He gave detailed explanations of what products to use and when, and fielded a wide range of questions from members. It was a thorough and expert demo that demystified the finishing process and dispelled some commonly held misconceptions.

Check out all the year's demos on our About/Prog page.

February 2023

February saw the welcome return of Chris Grace, one of the club's founding committee members, who demonstrated the turning of a hooded bud vase. As usual, Chris's demo was detailed and thorough, explaining clearly each stage of the process. He also showed his off-centre chuck modification that helped to damp down the vibration from having the log mounted off centre and out of balance. It was an absorbing and thoroughly enjoyable demo.

January 2023

January's meeting was a Zoom demo from Stewart Furini, to try out the new venue's wifi capabilities. Stewart demonstrated turning a shallow wide rimmed bowl in sycamore which was then textured and coloured. There were some minor blips with the connection in the first half of the demo but these were sorted out with a router reboot for the second half. Congratulations to the competition winners in the 'Freestyle' competetion.

December 2022 Meeting

A Merry Christmas and a Happy New Year to all our members. It was great to share mince pies in the final meeting of the year and see the wonderful display of Christmas decorations you turned.

November 2022 Meeting

Barry Chidlow could not do his turned illusion demo due to ill health, so Gordon stepped in and demonstrated the making of a peppermill with a Crushgrind mechanism - thank you, Gordon!

October 2022 Meeting

Gordon and Andy treated us to an evening of thread cutting. Two different methods were covered, with Gordon using a tap and die set for cutting wood threads, and Andy using the Simon Hope Threading Jig. Great results from both systems!

Don't forget about our Facebook group, which is a great way to keep in touch with members and to show what you have been doing! Find the group here.

August 2022 Meeting

We had a hands-on evening with three lathes in action for members to try out a range of turning techniques and tools. Thanks to Gordon Eaton, Dave Smith and Stewart Furini for running each lathe. There was an excellent response to the Chairman's Challenge on the topic of 'Box' with a great variety of styles on display. Congratulations to the winners!

Don't forget about our Facebook group, which is a great way to keep in touch with members and to show what you have been doing! Find the group here.

July 2022 Meeting

We were treated to a demonstration from professional woodturner Kevin Hutson for our July meeting. Kevin has a workshop in Borde Hill and has been demonstrating, teaching and selling his work for many years. He is a member of the Sussex Guild and you can see his work at one of the many exhibitions the guild holds throughout the year. Kevin demonstrated the skills needed to turn chess pieces, producing a bishop with a combination of skew and gouge work. After the tea break he worked on a square lidded box, one of his signature pieces. There was plenty of discussion about technique, methods and design.

Don't forget about our Facebook group, which is a great way to keep in touch with members and to show what you have been doing! Find the group here.

January 2022 Meeting

It was great to finally have a meeting with some lathes out, after the December social. The plan had been to have two lathes for members to use, but one of the lathes had not enjoyed lockdown very much and insisted on tripping out the hall's fuses each time it was turned on! Dave and Gordon managed admirably though, sharing the one remaining lathe and demonstrating some turning techniques and projects that were especially appreciated by the members old and new. Grahame demonstrated a Robert Sorby Pro-Edge sharpener and we even had the raffle and tea-break. Thank you to all the team who made thispossible.

Don't forget about our Facebook group, which is a great way to keep in touch with members and to show what you have been doing! Find the group here.

March Meeting 2020

This month was another practical evening with three club members demonstrating turning and Barrie Fitch showing laser engraving. Dave Smith was making hedgehogs and having interesting discussions with Anna Cates on skew angles, Gordon Eaton was turning bowls, and giving beginners some hands on experience, and Jim Young was demonstrating turning and finishing of small bowls.

Alongside this, a new camera set-up was being tried out and there was the Chairman's Challenge of 'Finial'. Congratulations to the three winners this month - Peter, Dave and Sandy.

See you on Saturday 21 March for the full day from Colin Simpson.

February Meeting

The first meeting of the year was very well attended and there was great interest in the bud vase demonstrations from Anna Cates, Barry Chidlow and Andy Heath. They all showed different approaches not just in shape and colour, but also design with off-centre turning and multi-holed vases.

It was also competition time with the Open Competition and there were plenty of entries this time round. It would be great to have as many or more for the bud vase competition to be judged in April.

.

December Meeting

We had planned to have a talk from our Chairman, Norman Billingham, about tool-making. However, this was not to be as Norman was unwell. We wish him a speedy recovery.

We did have our final competition of the year though, and our Chairman's Challenge was Christmas decorations...definitely a festive feel!

There will be no meeting in January, but we return in February with our Open Competition. Remember that subs are due in February.

We wish you all a merry Christmas and a happy new year.

November Meeting - Les Thorne does a Bowl

Les is a regular professional demonstrator to visit us, and he never disappoints. His demo this time was bowl turning and he took us through the whole process of shaping and hollowing the bowl, adding texture and colour, and covering the full range of cuts that are needed. There was something for everyone in his demo, from beginner to seasoned turner. As well as covering the basics, he also went through push and pull cuts in detail, focusing on different bowl gouge grinds, how to scrape and shear scrape with a long-grind bowl gouge, and then showed how to bead the outside of the bowl with a spindle gouge, how to put an undercut on the rim using a small bowl gouge, and how to finish off the bottom of the bowl. There was even some advice on sharpening. A great evening!

October Meeting - Gordon's Grinders

Gordon took to the lathe again this year for his second club demo and treated us to a session on making pepper mills using a Crushgrind mechanism. He showed us the two different versions available - shafted and shaftless. This is a great project for turners of all abilities, and a good one for novices to put a range of different turning skills into practice. A copy of the drilling and dimensions has been emailed to all club members. As well as educating us with his turning, he amused us with his humour, as always...and left us with the probing question of 'What was the best thing before sliced bread?'